The Bramwell Brown Blog

10 things you might not know about the Bramwell Brown Clock Workshop

Where is the Bramwell Brown Clocks’ workshop based?

The workshop is based near sunny Portsmouth in Hampshire, Great Britain. We’re especially proud to make all our clocks here in the UK.

What exactly does the team do in the workshop?

They receive and assemble all the parts that go into making a Bramwell Brown clock. Each clock has huge amounts of bespoke parts inside and it’s quite a complex process to manage.

Once the parts arrive, they’re all quality checked and then assembled and tested to a process that we’ve honed since the very first clock we built several years ago.

As well as this, the team have to continually put up with new and exciting ideas that Rob and Sarah develop which can often add to the complexity of manufacturing!

Are all the clocks and their internal mechanics hand assembled?

Yes, no robots or the like at the workshop. Just good, honest craftmanship and care for the clocks.

How many people work on assembling the clocks?

It changes throughout the year depending on how many clocks we have orders for! However, the hand-assembly team averages about 6 very hard working and diligent staff that we owe a lot of gratitude to.

How long does it take to assemble a clock from start to finish?

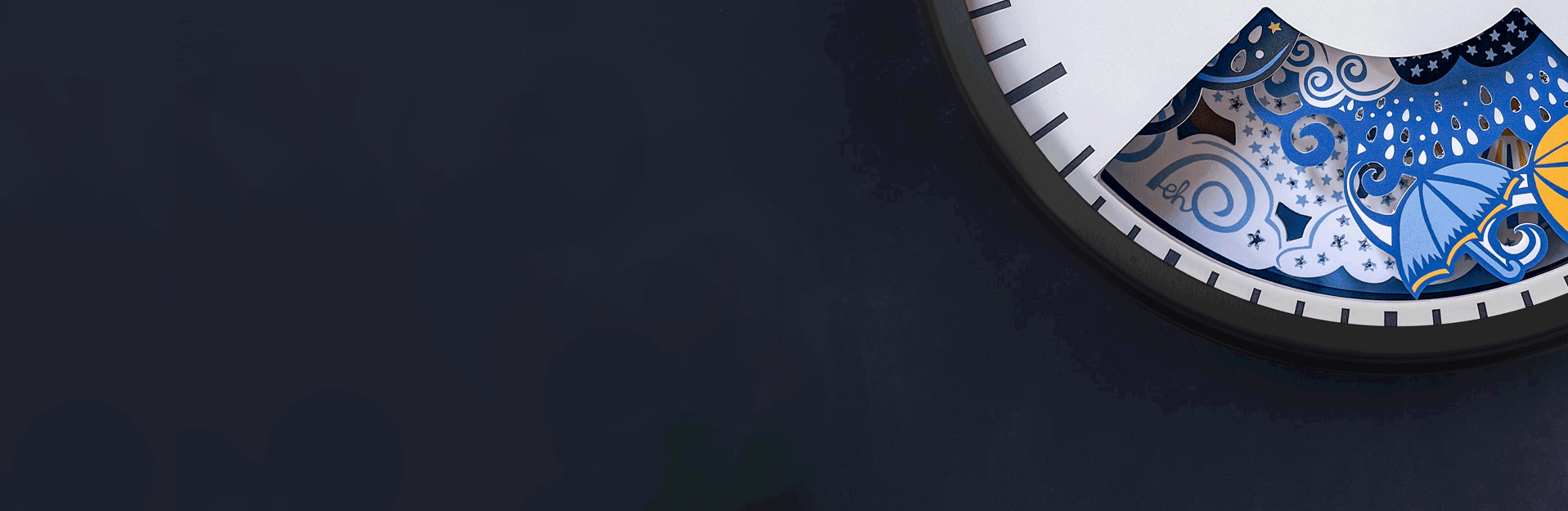

Each wall clock is mechanically tested at every stage of assembly, so it can take quite a long time for a clock to be put together and then be given the all-clear for dispatch! It can take even longer with our Limited Edition clocks where the weather artwork is specially printed at our Somerset-based printers prior to assembly of each clock.

Are all the different types of Mechanimated clocks assembled at the same workshop?

Yes, they are. The Limited Edition Weather Clocks are also made at the workshop in very small batches. Every now and then we'll make more to top up or replace exhausted stock levels.

Where does personalisation of the clocks take place?

Depending on the work required, it takes place at either the workshop or the studio at Somerset House in London. Whatever work is needed, all of our personalised clocks receive a huge amount of attention before they’re dispatched. We really enjoy seeing them finished and sent off, as each one has a little story about it depending on what the customer has requested.

What's the process from order, through the assembly line, to receiving your hand made clock?

Depending on what type of clock you’ve ordered, your clock will either be hand-assembled by the workshop team to order or we’ll select a clock from a recently finished batch. The regular Weather Clocks are made in small batches which means that sometimes we run low on stock in certain varieties whilst possibly waiting for new parts to arrive or space at the workshop to make some more. For Limited Edition Weather Clocks, as the clocks are built to order, the lead-time can be around 8 weeks. The bespoke parts needed for each clock can often take a while to receive prior to hand assembly.

Can you tell us a fun fact from the workshop?

After a period of unsuccessful negotiations (some say, with mediators), the assembly team still couldn’t agree to a favourite radio station so they now all listen to music on their headphones! Just like our clocks, everyone is slightly different!

Take me back to read more about the Weather Clocks